Plastic pipe production line extruder operation precautions

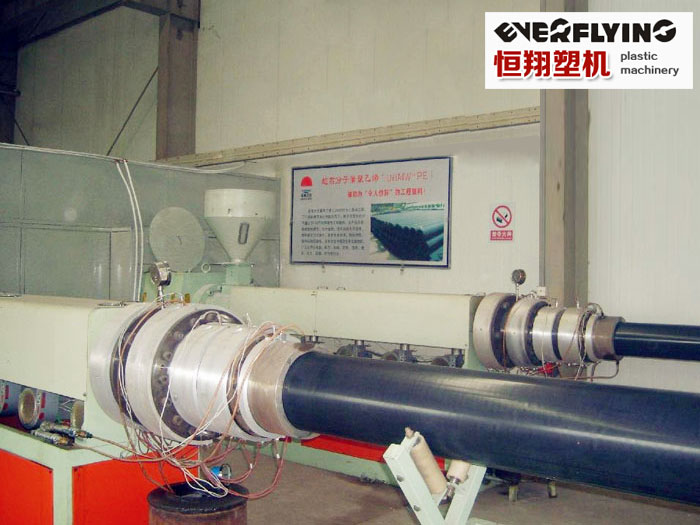

The plastic pipe production line has a control system that is then composed of an extruder, a head, a sizing cooling system, a tractor, a cutting device and a hopper. The extrusion principle of the extruder is to rotate in a heated barrel by using a screw with a beveled thread, and the plastic sent from the hopper is pressed forward to gradually heat the plastic, and the plastic is evenly plasticized to extrude the plastic. Head and mold molding. The extruder should pay attention to the following points during the actual operation:

1. Before starting the machine, check whether the heating coil is intact, whether the thermocouple is plugged in, and whether the temperature measurement is accurate.

2. At the time of starting, the heating temperature should be reached after the heating temperature reaches the set process temperature and keep warm for a certain period of time. In case of damage to the motor, screw and other components.

3. When the host starts, it must run at low speed for a few minutes, and drain the last remaining melt in the barrel. After the melt pressure and the host current are stable, the speed can be increased to prevent the spray from hurting the personnel.

4. The parameters such as temperature, current and melt pressure should be observed at any time during the operation of the equipment. Observe the heat of the motor and the gearbox. If there is an abnormality, find out the cause and eliminate it.

5, heating time depends on the size of the machine head, 63 machine head is not less than 3 hours, 250 head is not less than 6 hours, 450 head is not less than 8 hours.

6, the choice of mold: to choose the appropriate mold according to product specifications, if the mold is not properly selected will bring difficulties to production.

7, the protection of the mold: the quality of the mold determines the quality of the product, the material of the mold is generally mold steel, the surface is chrome-plated, the hardness is poor. Therefore, it must be protected during the disassembly and handling process, and there must be no scratches or collisions. Molds should generally not be placed directly on the ground and should be placed on rubber or wood. Do not hit with a hard weapon when changing the mold.

8. Adjustment of the concentricity of the core mold: The adjustment of the core mold of the solid wall tube production line follows the principle of “loose thin top thickness”. Loosen the screws in the direction of the small gap and tighten the screws in the direction of the large gap.

9. Protection of the heating coil: Generally speaking, the life of the heating coil is very long, and it is often damaged during the disassembly process. Therefore, the heating coil should be extra careful during the disassembly process.

| Previous:The working principle of the plastic extruder | next:Plastic extruder barrel wear maintenance method and precautions |

Add: No.3, Pengshan Road, Wudangshan Road, Laiwu high tech Zone, Jinan City, Shandong Province

Add: No.3, Pengshan Road, Wudangshan Road, Laiwu high tech Zone, Jinan City, Shandong Province